SRAM or Static Random Access Memory is found in many electronic devices from alarm clocks and thermostats to hard drives. Specialized SRAM is used as cache memory in microcontrollers and microprocessors. Static, because its contents stay in whatever state they were programmed, indefinitely, but only if power is applied. SRAM is volatile memory, meaning that its contents are lost if power is removed.

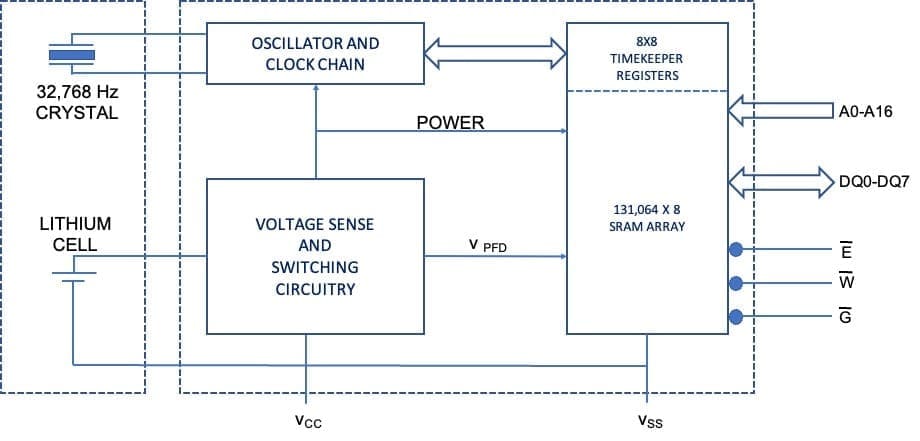

Lithium “coin cell” batteries are commonly used to retain data through power cycles. This implementation is called Battery-Backed SRAM and was often used in many industrial applications such as PLCs, Motor Control, Robots, HMIs etc. These real-time industrial automation systems log messages, and data related to alarms and contents of internal registers, state of environment variables etc. This functionality is generically called Data Logging.

Data logging has a few simple requirements – persistence, high endurance to survive many repeated read-write operations and fast & reliable writes in order to protect data in the event of unexpected power loss. Non-volatile memory devices, memory devices which retain data when power is removed, typically either have poor endurance or are not scalable to higher densities or both. Examples of such non-volatile memory devices include EEPROMs & Flash (both NOR and NAND Flash) – which suffer from low endurance, and, F-RAM & Toggle MRAM which are not scalable to higher densities. In the absence of scalable and reliable non-volatile memory devices, designers of industrial automation systems used battery backed SRAMs for data logging. The real question is not “Can I connect a battery to a RAM to prevent data loss during power outage?” but “Should I connect a battery to a RAM to prevent data loss during power outage?” since battery backed SRAM suffers from several drawbacks arising from its dependence on batteries.

The biggest drawback is that these systems require regular maintenance to monitor and replace batteries. Additional drawbacks include higher cost, bulky size, disposal of spent batteries, complicated RoHS compliance, higher access time and unpredictable data retention. In some cases, batteries and/or modules are soldered on the printed circuit boards which makes battery replacement all the more expensive. Not surprisingly, the usage of battery-backed SRAM is declining as better alternatives have become available. Spin Transfer Torque MRAM or STT-MRAM is one such alternative. STT-MRAM products such as Avalanche’s Persistent SRAM are high reliability, non-volatile, maintenance free and ecologically friendly.

| BB-SRAM | P-SRAM |

| Requires a battery | Battery free |

| Imposes ecological hazard, battery disposal problem, RoHS issues | RoHS compliant, environment friendly |

| Requires ongoing monitoring and periodic maintenance to ensure battery is healthy and data can be retained | No maintenance requirements |

| Battery vulnerable to moisture, shock and vibration | No vulnerability to moisture, shock and vibration |

| Requires additional board space | Standard expansion RAM board space requirements |

| Increases design complexity – must design additional supply voltage monitoring and switching circuitry, battery charge level monitoring circuitry | Standard expansion RAM design complexity |

| Increases software driver development – must develop driver to monitor battery charge levels and alert operator when charge level drops below a preset threshold to replace the battery | Standard expansion RAM driver development |

| Data retention depends on remaining battery charge at the time of power loss | Data retention is greater than 20 years |

Avalanche’s Persistent SRAM (P-SRAM) products are based on proprietary highly reliable STT-MRAM technology. These products offer truly non-volatile, random access memories that are ideal for applications that must store and retrieve data without incurring large latency penalties. They offer low power, and virtually infinite endurance and retention, and are ideal for non-volatile memory applications such as program storage and data logging in Factory Automation, Motor Control, Human Machine Interfaces, Smart Meters, and Multifunction Printers. P-SRAM products are available in a standard 35 nanosecond asynchronous SRAM interface as well as standard SPI and high-performance Q-SPI interfaces. While the parallel interface products enable easy migration from BB-SRAM implementations, the serial interface products simplify board design and are available in small footprint packages that are ideal for form-factor-constrained Industrial Internet of Things and Industry 4.0 applications.

Learn more about Avalanche Technology P-SRAM products HERE.